Automatic Press Product

Before the development of the automatic press, the ferric materials had to be weighed out manually and then fed into the mold by hand. While this method could produce magnet blocks with a density of 3.8 g/cm, results tended to be inconsistent due to affects attributed to human factors. The introduction of semi-automatic hydraulic presses (oil-based) did help increase densities to more than 4.5 g/cm; however, the press still suffered from poor efficiencies.

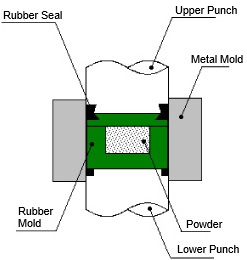

Nihon Denji Sokki developed its automatic RIP method to improve on results gained from the introduction of semi-automatic hydraulic presses. Our method is illustrated in the graph shown on the right. First the ferric materials are fed into the rubber mold’s cavity. Then as both the upper and lower punches work together to compress the powder within the rubber mold, the magnet block forms. Since the press acts in both vertical directions, the warping of the mold’s sides results in additional pressure from the horizontal direction.

Features:

- Wide selection of size & shape for molds

- Dimensional precision of ±0.5% possible

- High productivity (capable of making one press every 7 sec)

- High-quality uniform sintered bodies

- Wide variety of powder

- Rapid sampling using inexpensive mold

Comparison between methods:

| RIP | Hydraulic | Manual | |

|---|---|---|---|

| External Field | HF pulsed 6.5 T | 1600 kA/m | 800 kA/m |

| Block Density | 4.5 g/cm | 4.5 g/cm | 3.8 g/cm |

| Particle Size | 3.8 μm | 5 μm | 5 μm |

Thanks to the ability of this method to apply pressure equally in all directions, our isostatic rubber molds can offer you a high degree of pole alignment within your magnet blocks. The resultant isostatic pressure also prevents drift -- gaps forming between the mold’s inner wall and the powder within the mold’s cavity -- which has been observed in other methods.

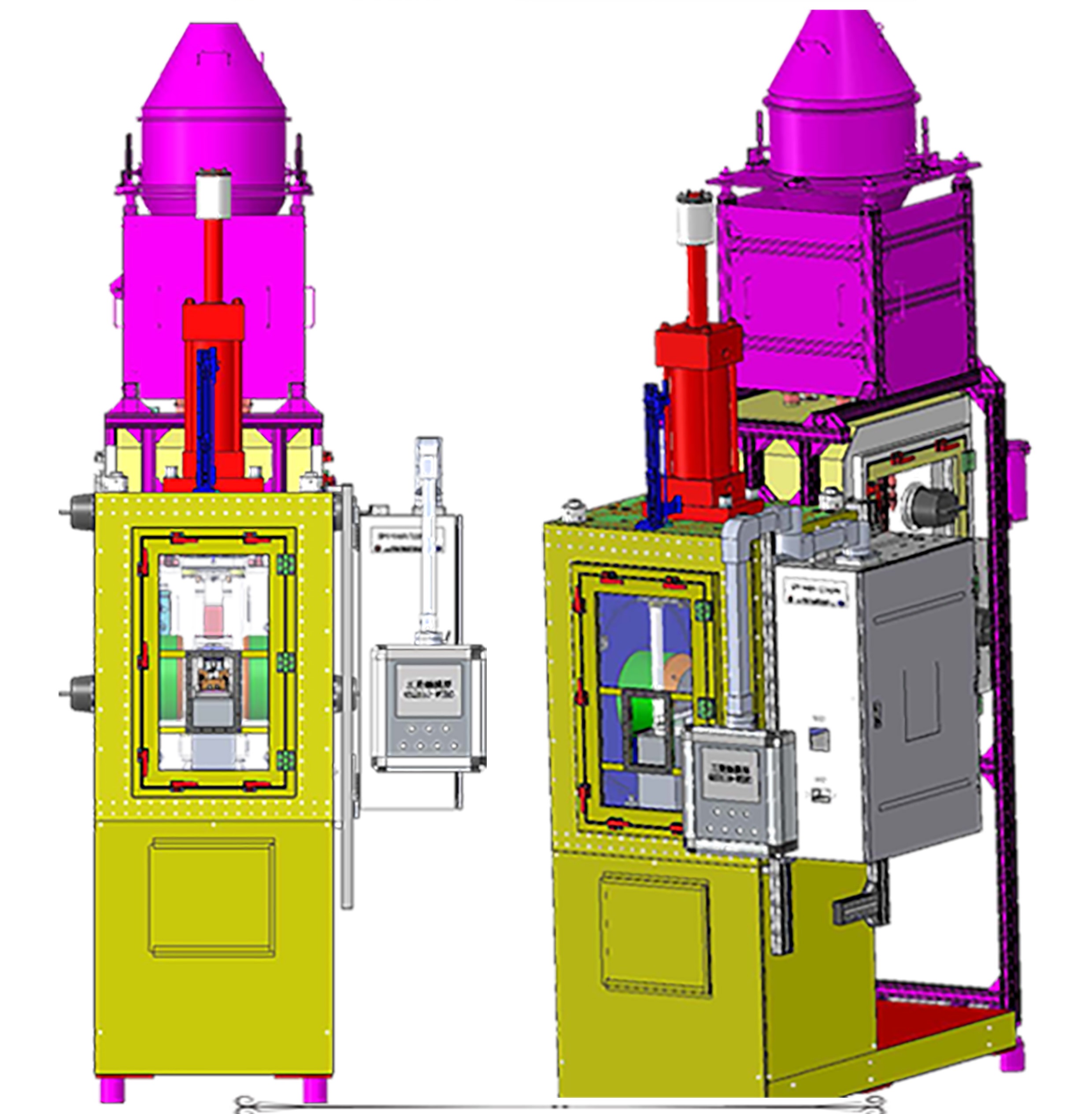

Since our rubber isostatic presses can form magnets from powders using either hydraulic or mechanical methods. Our custom designs have been gaining popularity worldwide.

We can offer you bespoke systems aimed at research into magnet materials or equipment used for validating your production processes. While most magnetic press makers typically offer their presses and magnetizers separately, we integrate both into a complete system. Therefore, we will need to consider your use case when determining the design of your system in order to match the requirements of your press with the spec for the field alignment equipment.

Features:

- Hydraulic Press = 100 Tons

- Alignment = Double-coil longitudinal, Repulsive Radial, or AC Magnetic Fields

- Power Supply = PD-1 Digital Controller, 200 V 3Φ, 150 A

- Output = 200 DCA at 200 V